About Company

ounded in 1969, FJLIME, China is one of the leading manufacturers. companies for Paper & Pulp Industry, which locates in Fuzhou, China, occupying an area of more than 61947m2.

FJLIME boasts comprehensive processing capabilities including machine tooling, cold work, welding, forge and press, and assembly. It has a professional team for design, testing, manufacturing, installation and commissioning with licenses for designing and manufacturing Type I and II pressure vessels, Class II metering certificate, and ISO9001 & ISO14001 certification.

Products

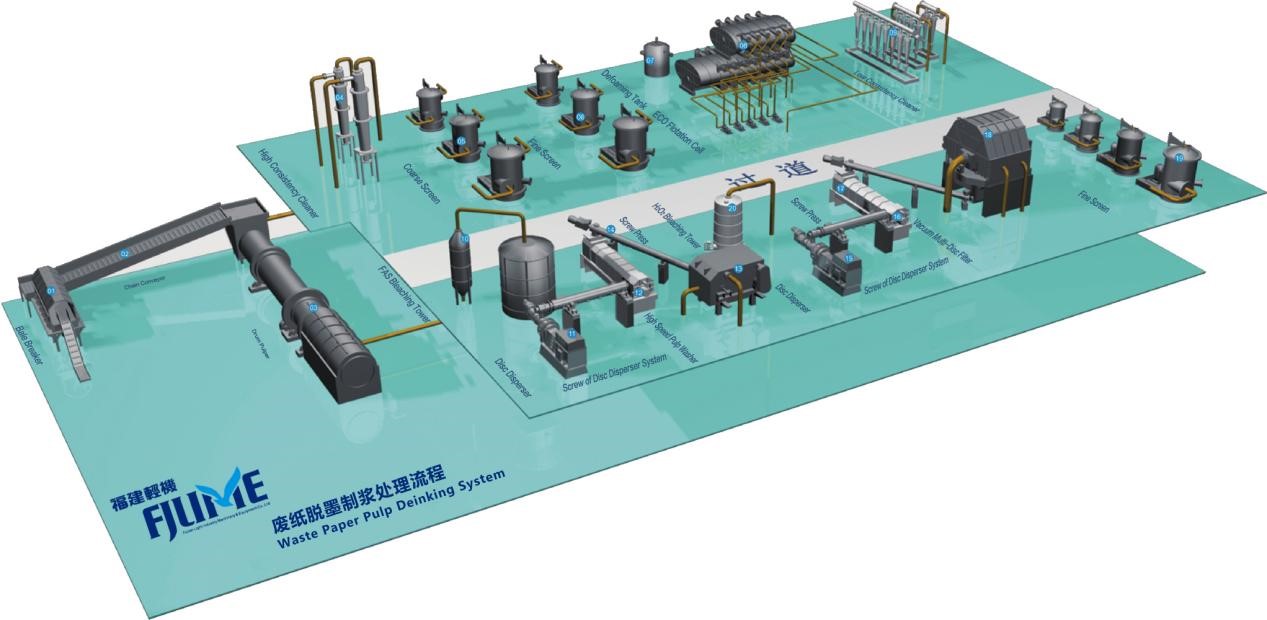

Waste Paper Deinking Pulp Line(DIP) Turnkey Service

The deinking process increases the whiteness and cleanliness degree of recycled paper, and further improves the paper qualities through mechanical and chemical process. FJLIME provides the complete DIP turkey service

1. Complete set of deinking equipment including pulping, screening, deinking, desanding, washing and concentrating and storage units

2. Automatic and Electrical control system

3. Engineering

4. Project management

5. Supervision service of installation, commissioning and start up

6. Operation training at site