About Company

Qingdao Qi An He Machinery Co., Ltd is your ideal supplier for pulp and paper making equipment and spares. Our refiner plates and fillings provide better fiber treatment result to make better paper quality, and wear-resistant material and processing for longer lifetime, and energy saving design features as extra benefit to our customers. Our filter baskets available for most OEM filter machine models, with super surface quality and slot tolerance, ensure filtration performance. We provide all type of screen basket, includes applications of coarse screening basket with drilled holes and barlists, or slot with barlists, fractionating screens, fine screens, outflow and inflow screen baskets, standard quality or headbox quality. We make screen rotor for different positions of coarse screens, fractionating and fine screens, outflow and inflow screens, headbox screens. Proven design for power saving, sufficient accept flow capacity, and better screening efficiency. Pulper rotors are available for replacement and maintenance. Products

Refiner Plate:

Our refiner plates and fillings provide longer cutting edges to have lower intensity or specific edge load (SEL), this property results to better fiber strength and length, fiber external surface gets well fibrillated, creating additional surface area for enhanced fiber-fiber bonding, to finally achieve a better paper quality, and wear-resistant material and best heat processing for longer lifetime, and a lower SEC energy saving design features as extra benefit to our customers.

Filter Basket:

Spare filter baskets available for most OEM filter machine models, with super surface quality and slot tolerance, ensure filtration performance and flow capacity.

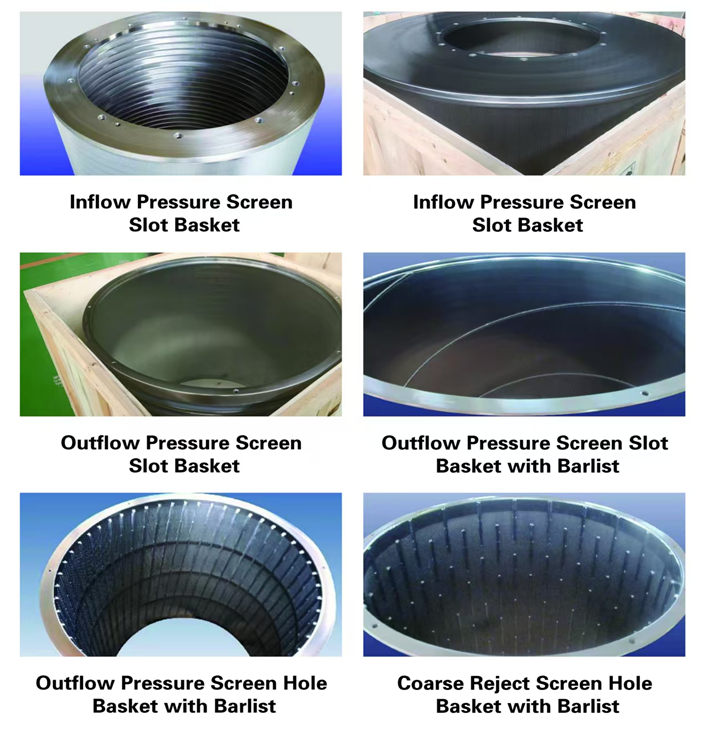

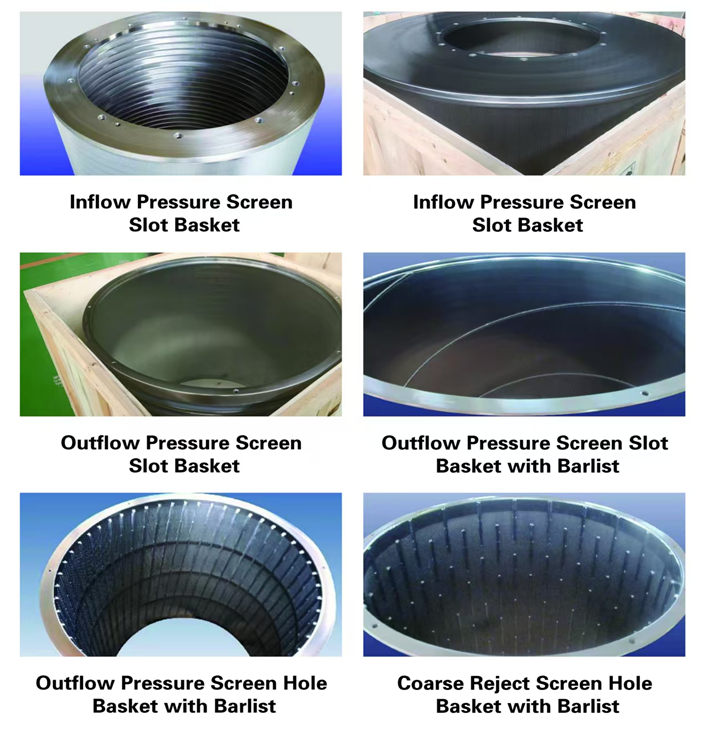

Screen Basket:

We provide all type of screen basket, includes applications of coarse screening basket with drilled holes and barlists, or slot with barlists, fractionating screens, fine screens, outflow and inflow screen baskets, standard quality or headbox quality, in stainless steel material available of SS304 or SS316L, a proven hard chrome coating applied to achieve better wear-resistant property for longer lifetime, experienced processing to have better slot tolerance for higher screening efficiency and sufficient accept flow.