About Company

Established in 1956 year as a Stated Owned Enterprise

18 years export experiences

A-Class boiler manufacturer

ISO9001-2000Quality Management System

Boiler commissioning service & Full-life after sale service

Annual production capacity of industrial boilers up to 5000 t/h and pressure vessels up to 6000 t/h.

Directly factory low price & Product-quality protection

Payment protection & Shipping protection .Products

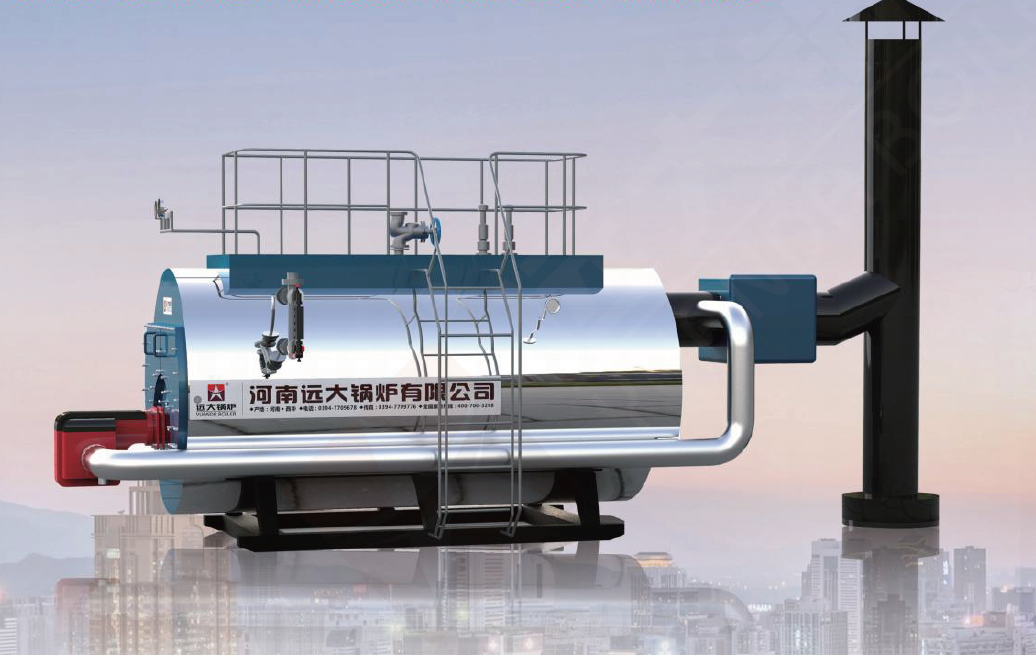

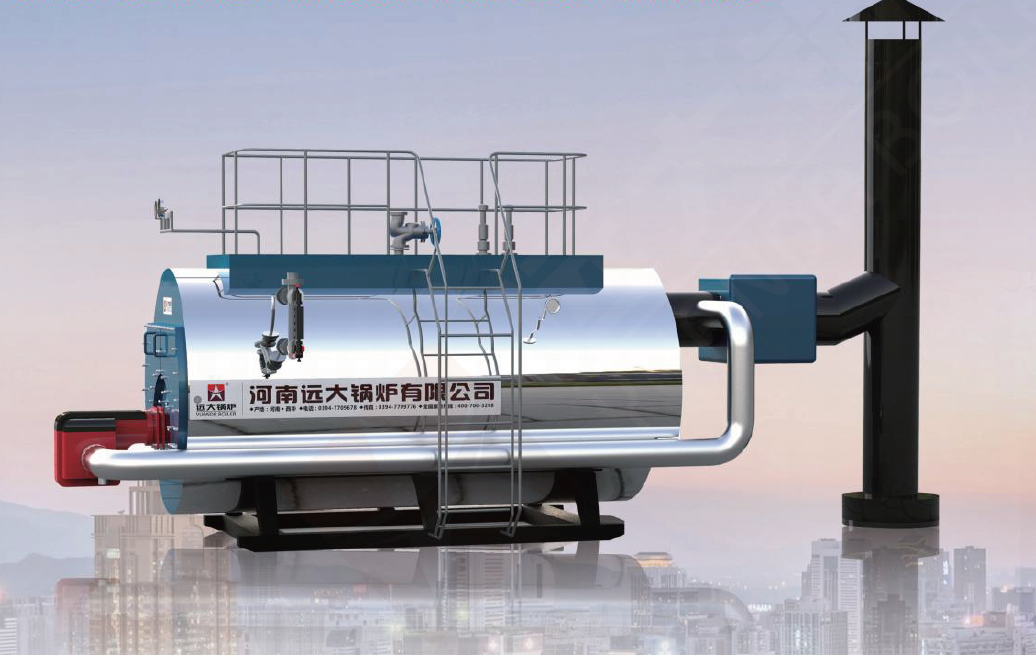

1. Adopting the latest technology of Swiss boiler, Stainless steel packaging, Coating with the hammer paint, beautiful and corrosion resistance; fully enclosed structure with double door-opening type smoke box, easy for maintenance.

2. 3-pass structure with spiral corrugated smoke pipe - increasing flue gas disturbance, enhanced heat transfer;

3. Design with 10% bigger size boiler pressure part to ensure sufficient steam production, and bigger size water volume assure good quality steam

4. Wet back structure With built-in smoke reversal chamber, decrease the temperature of back tube sheet, prevent cracking;

5. With Explosion-proof door, fully reduce the damage of boiler for detonation

6. Double layer 12cm Aluminum silicate insulation with strong force refractory casting materials, long life span, make boiler surface temperature is below 40 ℃, less heat loss with highest heat preservation effect

7. Smoke door is sealed with ceramic fiber ring design, can be re-used for long time; and avoid smoke/fuel gas leakage, safe to worker, low loss heat

8. Adopt advanced corrugated furnace, integral forging, bigger radiation heating surface, and strengthen heat transfer and eliminating welding stress., meet the requirements of heat expansion;

9. With diagonal bar design, increase the intensity of tube plate, to prevent the tube plate cracking;

10. Optimization of steam-water separation device, reduce the steam humidity, improving steam quality;

11. Integrated wiring device, wire control connection is more convenient, maintenance is simpler, beautiful after installation

12. Extremely low water level protection – except the normal 4 water level control, increased the 5th water level detection to ensure the boiler safety

13. More than 6% higher boiler thermal efficiency than normal boiler, lower operation cost in fuel investment

14. Equipped with vertical stainless steel pump, compact structure, low energy consumption;

15. Euro-imported burner equipment including with import valve group, quality is stable and reliable; Design with 20% bigger load burner to ensure sufficient thermal energy input, reduce burner running fatigue, extend the service life of burner

16. Intelligent control system with PLC and touch screen, simple and safe operation

17. Equipped with new condenser equipment, finned tube type made by ND steel with deoxygenation effect, strong thermal conductivity and greatly save fuel

18. The water treatment is flow sensor control system, automatic restoration and microcomputer operation;

19. Double safety valve and Double pressure gauge design -- -- backup protection, safe and reliable

20. Automatic control system to burner ignition, big & small fire on/off, fire switch; Gas high and low pressure protection; Gas leakage protection; Automatic feeding water and stop the pump; High and low water level alarm, low water level interlock; stop alarm for high exhaust temperature boiler;

21. Continuous feeding water device- prevent condenser vaporization, continuous use of latent heat of vaporization, increase thermal efficiency

22. Exhaust smoke temperature is low to 50-80 ℃,low nitrogen oxide and carbon dioxide emissions, smoke concentration and blackness meet for city environment requirements

23. 60 years of technical precipitation, mature production and technical team, stable quality.

24. Use China top steel material supply, like An’Yang Iron and Steel, Tianjin Seamless Steel Tube Factory with quality assurance.